Diamond tools

Among our range of diamond products and tools, we offer:

- Diamond and CBN grinding wheels: according to FEPA standards, custom-designed, machine lapping tools, hand-held hones, etc.

- Polycrystalline diamond and CBN tools: monoblock inserts, brazed inserts based on custom designs, various wear parts, etc.

- Electroplated diamond and CBN tools: custom-designed tools, discs, core drills, milling cutters, drills, saw blades, files, rifflers, spatulas, conical lapping tools, and specialized tools for specific industries (friction materials, GRP pipeline manufacturers, composite materials, etc.).

Natural diamond is pure carbon while synthetic diamond is made from pure carbon.

Synthetic diamonds are available in a wide variety of qualities which are perfectly controlled and well suited for specific applications and can undergo various treatments which improve their performance.

Cubic Boron Nitride (CBN) is made up of boron and nitrogen. It does not contain carbon, but it is produced by a synthetic diamond-like process. It is less hard than diamond but more resistant to high temperatures. Like synthetic diamonds, CBN can undergo treatments that modify its characteristics, depending on its use.

Diamond wheels :

- Tungsten carbide

- Ceramic, “cermet”, Alumina

- Glass, crystal

- Ferrite

- Refractory materials

- Natural and artificial stones

- Precious and semi-precious stones

- Graphite

- Composite materials

- Polycrystalline diamond and CBN

- Carbide, steel

- Tungsten, titanium

Grinding wheels in CBN :

- High speed steels HSS

- Hard steels >= 45HRC

- Chrome steel

- Matrix steel

- Hard and extra hard cast iron

- Special alloys (Nickel-Cobalt)

- Stellite

Applications of diamonds

for of tools and industrial parts manufacturing :

From their physical properties arise their applications : high density requiring little space, high elasticity modulus, very high absorption coefficient for penetrating radiation, remarkable resistance to striking an electric arc, very high melting point of all metals, good mechanical resistance and machinability.

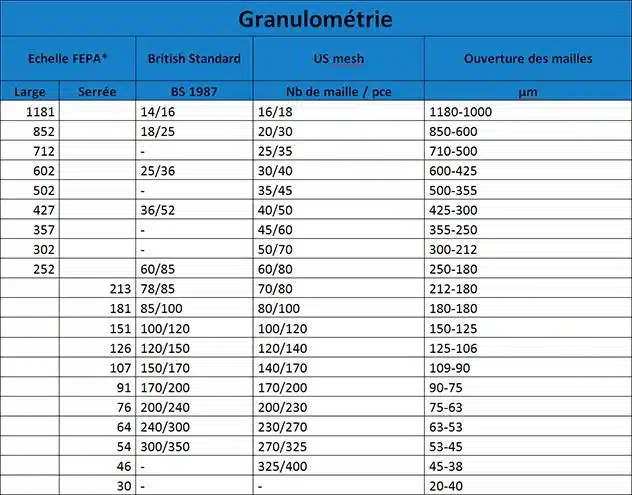

Granulometry of abrasives :

For any questions, you can contact us.